CONTACT DETAILS

Telephone: 0086-312-8072668

Fax: 0086-312-8072669

Mailbox: changdidianli@163.com

Website: en.changdidianli.com

Address: Wuluohou Industrial Zone, Weicun Town, Qingyuan District, Baoding City, Hebei Province

Anticorrosive electrolytic ion grounding electrode

The high-efficiency grounding electrode adopts high-carbon graphite compound pole body inside and copper, nickel, chromium alloy plating on the outside, ensuring high conductivity and corrosion resistance. The service life is increased. The electrode body is equipped with special electrolytic ionic compounds and polymer hygroscopic materials. After moisture absorption and deliquescence, the active ions penetrate into the soil around the ground electrode to improve the dispersion conditions. In the application of high soil resistivity, it can still obtain low The ground resistance.

1. Product performance and characteristics

The electrolytic ion grounding electrode is a new type of grounding material developed, produced and implemented by our company using foreign technology and implementing services and technical support.

The electrolytic ion grounding electrode tube is filled with high-carbon ion compound crystals, and the exterior is made of copper and steel. To ensure conductivity and long service life. The inner filling material of the conductor contains a special electric ion compound, which can fully absorb the moisture in the air. Through deliquescence, active electric ions are effectively released into the soil, combined with the moisture in the soil and the air, and further promote the slow release and resistance reduction of the external conductor, and keep the resistance value stable for a long time. The compound inside the conductor gradually turns into a colloidal transparent state with time. We use the conductive properties of colloidal compounds to enable the entire system to be in a state of ion exchange for a long time, thus forming an ideal electrolytic ion grounding electrode.

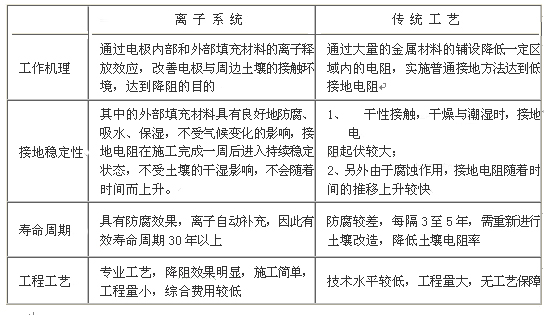

2. Compared with the traditional grounding modification process, the ion grounding electrode has the following characteristics

3.working principle

The electrolytic ion grounding electrode adds a reversible slow-release filler to the grounding electrode. This filler has the characteristics of water absorption, water release and reversibility. When it absorbs water, it can absorb 100-500 times of its own moisture. When the external environment is dry and lacking, it can completely release the moisture it possesses to reach the surrounding moisture balance. This reversible reaction effectively ensures the effectiveness of the internal environment of the shell. Humidity ensures the stability of grounding resistance. After the ions generated in this way absorb the earth's moisture, they can effectively release active electrolytic ions into the surrounding soil through deliquescence, making the grounding electrode an ion generating device, thereby improving the surrounding soil quality to meet the grounding requirements. The external filler of the grounding electrode produces chemical treatment for the crust soil through the interaction with the internal electrolytic ion filler, which reduces the resistivity of the crust soil. At the same time, a transition zone is formed between the slow-release grounding electrode and the earth soil. The equivalent cross-sectional area of the grounding electrode and the contact area of the soil are increased, the contact resistance between the grounding body and the soil is eliminated, the electric field distribution in the ground is improved, and the filler has good permeability and penetrates deeply into the soil and rock joints. , Forming a tree root network, increasing the drainage area in the ground.

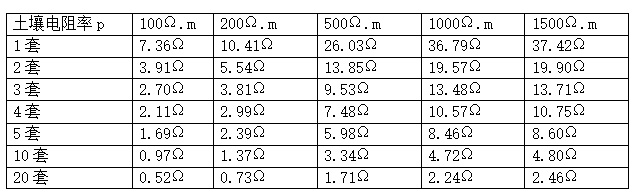

4. Design method and reference quantity

Calculation formula: n≈(0.0275*ρ/R)-0.4

n is the number of ground electrodes required

ρ is soil resistivity

R is the large value of grounding resistance

If the soil resistivity is extremely high (above 1000 ohm.m), you can multiply the above calculation result by the adjustment coefficient k, which can take a value of 1.2 to 1.5. If the soil resistivity is high, the value of k will increase.

5. Application scope and method of use

Due to its good anti-corrosion performance, excellent electrical conductivity and unique design technology, electrolytic ion grounding electrodes are widely used in grounding projects in important places such as communications, electricity, petrochemicals, finance, networks, and electronics. They are especially suitable for harsh soil conditions and construction Conditions are restricted and grounding works with high technical standards.

Construction method

1. drilling:

Drill holes with a diameter of 160mm×3150mm/1550mm vertical to the ground in the selected construction site.

2. Preparation of filler:

Mix the filler with water to form a paste (slightly thick and fluid) and pour it into the hole drilled in advance to a depth of about the hole;

3. Implanted ground electrode:

(1) Disassemble the ground pole sealing tape;

(2) Implant the ground electrode in the hole, and the top of the ground electrode is flush with the ground plane;

(3) Connect the lead wires;

(4) Fill the rest of the filler around the grounding electrode to 100mm from the top of the grounding electrode, measure the grounding resistance, and fill it with soil around the electrode after reaching the grounding requirements.

Note: When one set of grounding electrode fails to meet the ground resistance requirements, two or more sets can be used in parallel, and the distance between rods should not be less than 5M; the lead wire adopts 50mm2 multi-strand copper wire, and the lead wire and the ground electrode body Carry out crimping and contact corrosion protection.