CONTACT DETAILS

Telephone: 0086-312-8072668

Fax: 0086-312-8072669

Mailbox: changdidianli@163.com

Website: en.changdidianli.com

Address: Wuluohou Industrial Zone, Weicun Town, Qingyuan District, Baoding City, Hebei Province

1 Overview

The Jichangdi brand CDM series grounding module product is a grounding body mainly made of conductive non-metallic materials. It is a special product used to reduce grounding resistance. It is suitable for various types of soil environments and has significant application in areas with high soil resistivity. The superiority.

Compared with traditional grounding bodies, this product has the advantages of high resistance reduction efficiency, stable grounding resistance, reduced ground potential counterattack, long service life, corrosion resistance, non-toxic and environmental protection, and convenient construction and installation. It is widely used for lightning protection grounding and safety protection. Grounding, AC working grounding, DC working grounding, anti-static grounding, shielding grounding and other special grounding.

2. Working principle and function

The grounding resistance of the grounding grid is mainly composed of the resistance of the grounding body and its connecting materials, the contact resistance between the grounding body and the surrounding soil, and the diffusion resistance of the ground current in the soil. The contact resistance between the grounding body and the soil and the ground current are The diffusion current in the soil is the main part of the grounding resistance, which is more than 98% of the grounding resistance of the station.

Traditional grounding bodies are mostly metal conductors, such as flat steel, round steel, angle steel, steel pipe, copper rod, copper plate, etc. The use of traditional grounding materials for grounding grids is greatly affected by the season, the grounding resistance is not stable enough, and the service life of the grounding grids is relatively short. It is difficult to solve the grounding problem under the conditions of particularly high soil resistivity.

The Jichangdi brand CDM series grounding modules are mainly made of metal materials with very good conductivity and stability, and are made of metal materials with anti-corrosion treatment on the surface, which are extruded by special equipment.

Compared with traditional grounding bodies, this product has the following remarkable features:

(1) Reduce the contact resistance. The main material of the Jichangdi brand CDM series grounding module is similar to the physical structure of the soil, and can be integrated with the soil, making the effective contact area of the grounding body and the soil many times larger than that of the metal grounding body. The effective dissipation area of the grounding body greatly reduces the contact resistance between the grounding body and the soil, so it can significantly improve the grounding efficiency and reduce the land area occupied by the ground network.

(2) Stable grounding resistance: Jichangdi brand CDM series grounding module itself has strong moisture absorption and moisture retention ability, which keeps the surrounding soil moist, ensuring that the grounding module can effectively perform the conductive role; at the same time, the conductive properties of the conductive objects in the grounding body are not affected by the Due to the influence of seasonal changes such as dry humidity, high and low temperature, it can provide stable grounding resistance.

(3) Reduce ground potential counterattack: The non-metallic materials of the Jichangdi brand CDM series grounding modules form a relatively smooth and low resistance area between the metal and the soil with a huge difference in resistivity. When a large current impacts, it can reduce the grounding body, The transient potential gradient of the ground wire reduces the step voltage and contact voltage and reduces the probability of ground potential counterattack.

(4) Long service life: The main body of the Jichangdi brand CDM series grounding module is made of anti-corrosion material, and its metal frame is made of metal materials with anti-corrosion treatment on the surface. Therefore, the overall corrosion resistance of the grounding body is excellent, and the service life is up to More than thirty years.

3. Performance characteristics

(1) Corrosion-resistant, non-toxic, long service life, convenient installation, and reduce construction workload;

(2) It can absorb moisture and keep moisture and has low grounding resistance;

(3) The resistance against high current impact will not increase, nor will it harden, become brittle, or break;

(4) It can effectively reduce the grounding resistance of high resistivity soil;

(5) The grounding resistance is less affected by the season, and the resistance value can remain stable for a long time.

4. Technical indicators

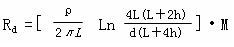

| Model | Appearance (mm) | Quality | Power frequency grounding resistance | Resistivity at room temperature |

| Low resistance grounding module CDM-I type | 500×400×60 (Flat shape) | 20kg | ≤1.5Ω | ≤0.3Ω.m |

| Low resistance grounding module CDM-Ⅱ type | Φ150×800 (Cylindrical) | 25kg | ≤1.2Ω | ≤0.3Ω.m |

| Low resistance grounding module CDM-Ⅲ type | Φ260×1000 (Plum shape) | 80kg | ≤1Ω | ≤0.3Ω.m |

5. Dosage calculation

According to the measured soil resistivity, the following formula is used to calculate the amount of resistance reduction module.

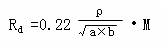

① Cylindrical, vertically buried, grounding resistance of a single module:

② Flat type, horizontally buried, grounding resistance of a single module:

③ Total ground resistance after parallel connection:

In the formula: ρ —— the measured soil resistivity of the buried stratum (Ω.m);

L —— the length of the cylindrical module (m);

d —— the diameter of the cylindrical module (m);

h —— the buried depth of the grounding module (m);

a.b —— the length and width of the flat module (m);

M —— Module adjustment factor, 0.32 for flat shape and 0.34 for cylindrical shape;

n —— the number of grounding modules;

K —— Module utilization factor, 0.55-0.85 (the more the number of modules, the smaller the value of K).

6. Engineering construction technology

The quality of the grounding system is largely determined by the construction quality, so it is necessary to master the correct construction methods and process quality requirements. The construction of grounding works should generally follow the following basic principles:

(1) Within the effective length, choose to bury the grounding body in a place with low soil resistivity as much as possible.

(2) The buried location of the grounding body should be far away from the heat source.

(3) The buried location of the grounding body should try to avoid places with strong corrosive substances.

(4) The buried location of the grounding body should be as far away as possible from people's frequent activities, otherwise measures should be taken to prevent step voltage hazards.

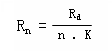

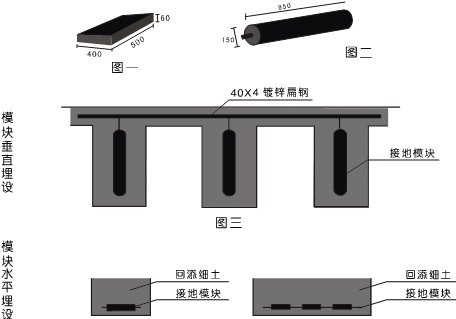

(5) According to the actual needs of the project, the CDM-I grounding module is generally used for horizontal burying, and the CDM-II module is generally used for vertical burying, or in any other form suitable for terrain conditions.

(6) The buried depth of the grounding body should not be less than 0.8 meters, and it should be buried deeply if conditions permit.

(7) The buried spacing of vertical grounding bodies should be more than 5 meters, and the buried spacing of horizontal grounding bodies should be 5-10 meters.

(8) The same kind of corrosion-resistant metal materials must be used, and the electrical connection of the buried part of the grounding system must be ensured by welding. Lap welding shall be used, and the lap length shall not be less than twice the width of the flat steel or 6 times the diameter of the round steel, and shall be welded on multiple sides. It is recommended that the weld length is not less than 100mm. There must be no false welding or missing welding.

(9) Welding slag must be carefully removed, and asphalt or other anti-corrosion materials should be coated on the welding part, and the anti-corrosion treatment should be done.

(10) Backfill with original soil or fine clay, at least 30-50cm fine soil around the grounding body should be ensured, and proper amount of watering should be fully implemented.

legend:

7. Packaging, storage and transportation

(1) Jichangdi brand CDM series grounding modules are packed in cartons, one for each CDM-type.

(2) The Jichangdi brand CDM series grounding module should avoid mechanical damage during storage and transportation, and prevent high temperature and sun exposure.

(3) The storage period of Jichangdi brand CDM series grounding module is two years.

8. Reference table for the amount of grounding module

| Ground resistance (Ω) Soil resistivity (Ω.m) | 10Ω | 5Ω | 4Ω | 2Ω | 1Ω |

| 100Ω.m | 2Piece | 4Piece | 5Piece | 9Piece | 18Piece |

| 200Ω.m | 4Piece | 7Piece | 9Piece | 18Piece | 35Piece |

| 300Ω.m | 6Piece | 11Piece | 14Piece | 27Piece | 53Piece |

| 400Ω.m | 7Piece | 14Piece | 18Piece | 35Piece | 70Piece |

| 500Ω.m | 9Piece | 18Piece | 22Piece | 44Piece | 88Piece |

| 600Ω.m | 11Piece | 21Piece | 27Piece | 53Piece | 105Piece |

| 700Ω.m | 13Piece | 25Piece | 3lPiece | 62Piece | 123Piece |

| 800Ω.m | 14Piece | 28Piece | 35Piece | 70Piece | 140Piece |

| 900Ω.m | 16Piece | 32Piece | 40Piece | 79Piece | 158Piece |

| 1000Ω.m | 18Piece | 35Piece | 44Piece | 88Piece | 175Piece |

Note: Due to the different environments in high soil resistivity areas and permafrost areas, different design schemes, and different construction quality, the actual effect may deviate from the theory.