CONTACT DETAILS

Telephone: 0086-312-8072668

Fax: 0086-312-8072669

Mailbox: changdidianli@163.com

Website: en.changdidianli.com

Address: Wuluohou Industrial Zone, Weicun Town, Qingyuan District, Baoding City, Hebei Province

Product Introduction

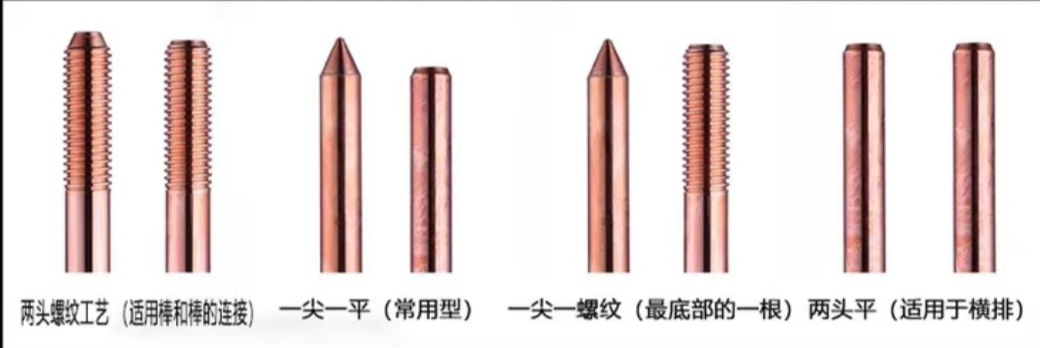

Jichangdi brand CD series copper-clad steel ground rods are made of high-quality low-carbon steel with a carbon content of 0.10%-0.30%. The high-conductivity electrolytic copper is uniformly covered on the round steel surface with a thickness of 0.25 -0.5mm, this process can effectively slow down the speed of ground rod oxidation in the ground. This ground rod can be divided into two types: single and combined. The single rod can be pointed at one end and flat at the other end, and can be threaded on the roll with each pointed end. The two ends of the combination need to be threaded on the roll. The thread is processed by the roll thread groove, which maintains the tight connection between steel and copper, ensures high strength, and has excellent electrical grounding performance. This product has been widely used in the grounding system of electric power, petrochemical industry, transportation, civil construction, and large-scale mechanical equipment. It has the characteristics of long service life, economy, and excellent electrical conductivity.

Structure

Main rod: The ground rod is made of high-quality cold drawn element steel, and is cast with red copper (thickness 0.3~0.5MM, copper content 99.9%) with special equipment to ensure its excellent electrical conductivity and mechanical strength. This product has excellent Anti-corrosion performance.

Connecting pipe: A copper connecting pipe can be used to connect the rods, which has a better anti-corrosion effect. The rod is in close contact with the rod, and the driving force directly acts on the ground rod when the ground rod is driven into the ground or when the driving drill is used to drill into the ground. Divided into threaded connection and non-threaded connection.

Drive head: It is made of high-strength alloy steel, which can ensure that the drive force goes underground smoothly.

Alloy tip: to ensure penetration into the ground under complex geological conditions.

Application

Copper-clad steel grounding materials are suitable for general environments and special environments where damp, saline-alkali, acidic soil and chemically corrosive media are produced. They are widely used in power plants, substations, transmission line towers, communication base stations, airports, railways, subway stations, and various Lightning-proof grounding, anti-static grounding, protective grounding, work grounding, etc. in high-rise buildings, microwave relay stations, network computer rooms, petrochemical plants, oil storage depots, etc.

Main technical parameters and specifications of copper-plated steel grounding products

1.99.95% pure copper and Q235 low carbon steel

2. Copper layer thickness 0.254mm

3. Tensile strength 570N/mm2

4. The ground rod can be bent 1800 copper layer without cracks and peeling

Specification model | Diameter(mm) | length(mm) | Copper layer thickness(mm) | Kg/m | |||||||||

1 | 12.7 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 1.00 |

2 | 14 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 1.22 |

3 | 14.2 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 1.25 |

4 | 15.8 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 1.55 |

5 | 16 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 1.59 |

6 | 17.2 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 1.83 |

7 | 18 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 2.01 |

8 | 20 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 2.48 |

9 | 22 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 3.00 |

10 | 25 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 3.87 |

11 | 30 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 5.57 |

12 | 32 | 1200 | 1220 | 1500 | 1800 | 2400 | 2440 | 2500 | 3000 | 0.254 | 0.5 | 0.8 | 6.34 |

Product performance of copper-plated steel grounding electrode

Serial number | Technical content | Technical Parameters |

1 | Conductor diameter | 8.47/9.50/12.70/14.20/17.20/23.10mm |

2 | Length of finished product | 1.52/1.83/2.44/3.05/3.66/4.56m |

3 | Conductivity | Good conductivity and stable electrical performance |

4 | Coating thickness | mil/0.254mm |

5 | Product Type | Non-threaded flat head/non-threaded tip/threaded flat head/threaded tip |

6 | Production Process | The four-dimensional electroplating method adopts the domestically pioneered nano alkaline copper pre-plating technology. The principle is to finely control the density and deposition speed of nano-scale particle clusters formed by complexes and Cu2+ in the plating solution by constructing an aerodynamic field environment, and construct a new type of nano-scale particle deposition model between mace and steel, cathode The metal deposition forms a nano-scale alkaline copper particle crystal coating structure. The nano-scale crystal coating has good compactness and a highly activated surface, which greatly enhances the affinity between the coatings and makes the product binding force reach the standard. The finished product has excellent mechanical strength, ductility and corrosion resistance. |

7 | Service life | According to the test data of a 45-year underground corrosion research project carried out by the National Bureau of Standards, the average annual corrosion rate of copper is 0.002524mm. According to the requirements of UL467, IEEE80 and the national power industry DL/T1312 standards, such metal conductors have small copper layers Calculated with a thickness of 0.254mrn, the service life of the copper-plated steel grounding conductor can be guaranteed over 100 years. |

8 | Soil suitability | That is, it is suitable for ordinary environment, and it is more suitable for any harsh soil environment such as mountains, rocks, strong acid and alkali. |

9 | Packing | 10, 20, 50 pieces/shelves individually packaged, with product qualification certificate and original nameplate |

10 | Certification content | Products have passed the authoritative UL, CE certification |

11 | Scope of application | Applied to the vertical grounding part of the grounding grid, it can replace the traditional galvanized steel and pure copper |

Combined grounding electrode accessories list

Serial number | Product name | Product specifications | Material | Thread type inch | Anti-corrosion process | Weight kg |

NO.1 | Connector | LJ-14.2-E | Silicon brass | 5/8(Inch thread) | No | 0.12 |

NO.2 | Connector | LJ-14.2-G | Silicon brass | M16(Metric thread) | No | 0.12 |

NO.3 | Connector | LJ-17.2-E | Silicon brass | 3/4(Inch thread) | No | 0.17 |

NO.4 | Connector | LJ-17.2-G | Silicon brass | M18(Metric thread) | No | 0.17 |

NO.5 | Drive head | QD-14.2-E | 45#Steel | 5/8(Inch thread) | Toasted blue | 0.08 |

NO.6 | Drive head | QD-14.2-G | 45#Steel | M16(Metric thread) | Toasted blue | 0.08 |

NO.7 | Drive head | QD-17.2-E | 45#Steel | 3/4(Inch thread) | Toasted blue | 0.12 |

NO.8 | Drive head | QD-17.2-G | 45#Steel | M18(Metric thread) | Toasted blue | 0.12 |

NO.9 | Ground breaking tip | JD-14.2-E | 45#Steel | 5/8(Inch thread) | Toasted blue | 0.06 |

NO.10 | Ground breaking tip | JD-14.2-G | 45#Steel | M16(Metric thread) | Toasted blue | 0.06 |

NO.11 | Ground breaking tip | JD-17.2-E | 45#Steel | 3/4(Inch thread) | Toasted blue | 0.08 |

NO.12 | Ground breaking tip | JD-17.2-G | 45#Steel | M18(Metric thread) | Toasted blue | 0.08 |