CONTACT DETAILS

Telephone: 0086-312-8072668

Fax: 0086-312-8072669

Mailbox: changdidianli@163.com

Website: en.changdidianli.com

Address: Wuluohou Industrial Zone, Weicun Town, Qingyuan District, Baoding City, Hebei Province

Definition of exothermic welding

Exothermic welding is a simple, high-efficiency, and high-quality metal joining process. It uses the chemical reaction heat of metal compounds as a heat source, and directly or indirectly heats the overheated (reduced) molten metal. It works in a special graphite mold. A welded joint of a certain shape and size is formed in the welding chamber to meet the engineering requirements. At present, exothermic welding has generally replaced the previous mechanical and physical connection methods between metals. Many international standards recommend the use of exothermic welding processes in grounding systems, such as IEEE, IEC, NEC, ASME, etc.

Principle of exothermic welding reaction

3Cu2O+2AL—6Cu+Al2O3+Heat(2537℃)

Advantages of exothermic welding

The resulting solder joints are pure copper, which belongs to atomic bonding. The corrosion resistance, electrical conductivity, and mechanical strength of the solder joints are not lower than the conductor itself, avoiding the problem of easy loosening of mechanical and physical connections;

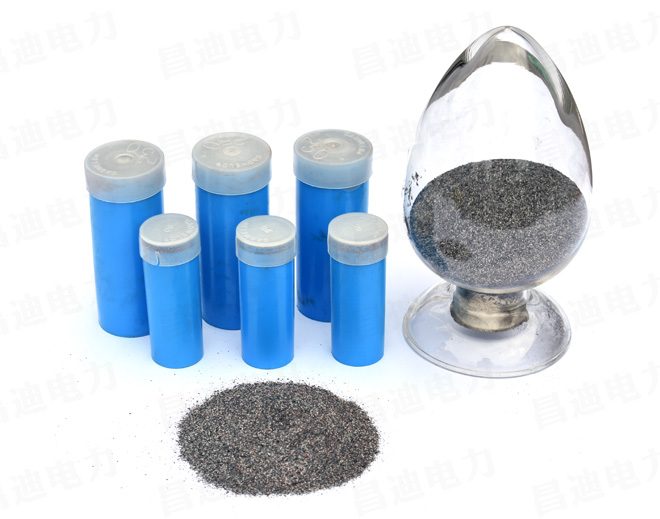

The enhanced one-piece exothermic flux is a non-dangerous product and adopts a sealed and waterproof design. The flux does not contain phosphorus, magnesium and other harmful materials to the human body, which is convenient for transportation and storage;

Component packaging can be provided according to the connection method. Under the premise of fully ensuring the standardization of welding quality, it not only reduces the damage to the metal base metal by welding to a minimum, but also greatly improves the service life of the mold;

The welding method is simple and easy, no professional skills are required, the quality of the welding point is highly standardized, the materials and tools for welding are light in weight, easy to carry, and no external power supply or heat source is needed when welding; high-strength, high-purity, high-quality graphite raw materials are used to produce molds , Graphite has high density to ensure low adhesion of welding residue and long mold life. The design from reaction, diversion to welding is reasonable to avoid mold explosion, welding copper splash and other phenomena, and the welding quality is high; the domestic authoritative certification of IJL, CE' and RoHS has been passed.

Product performance of exothermic flux

Serial number | Technical content | Technical Parameters |

1 | Net weight of contents | 65g/90g/115g/150g/200g/250g ⋯ |

2 | Content composition | The welding flux contains 75-82% copper oxide and 18-25% catalyst. The corrosion resistance of the welded joint is stronger than that of the conductor itself. It does not contain phosphorus or magnesium, and is non-toxic and harmless. |

3 | Production Process | Automatic filling system, high consistency of filling ingredients |

4 | Service life | Unlike general domestic products, the humid environment has basically no impact on product performance, and the material loss rate due to waste is extremely low, and the theoretical life span is indefinite |

5 | Packing | The S2-31 series of enhanced one-piece fluxes are non-dangerous goods. They are packaged according to different welding requirements to ensure the standardization of solder joint quality and increase the service life of the mold by more than 30%. The product qualification certificate, original nameplate and required aluminum are attached. sheet |

6 | Certification content | Products have passed authoritative UL, CE and RoHS certifications |